- Home

- About Himin

- Company profile

- Himin Cases

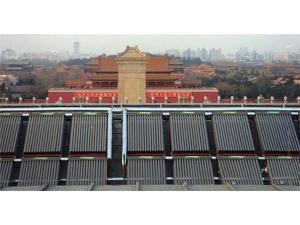

So far, the solar hot water project in the memorial hall of Chairman Mao is biggest project used U-pipe solar collector, the project could provide 15t hot water every day. The project is made up of U-pipe solar collector, pipe system, heat exchanger system, tank system, water treatment system, remote control system, variable frequency water supply system, anti-overheat system and electric boiler auxiliary heating system. The system also equipped the only remotemonitoring system in the solar thermal industry, the monitoring center locates in Himin group, it could monitor the system all day in other city.

This project has approved by Chinese administration with total PV installation capacity 2.0114MW ,total area 22300m2,10057 PC solar panels, which this system produces electricity by itself for itself and the surplus power can be on-grid with maximum power 2.0MW.This energy-saving effect of the project is greatly obvious with supplying green power 2320000kWh ,saving 835200 standard coal, reducing 2171500 CO2 ,20000SO2 ,5800NxOx,8400 dust every year.

In 2011, Himin Solar supplied the key part of coated steel tube to PE2 project in Spain. The total tube was 27,000 long. It was not the first project powered by Himin patented coated steel tube. Puerto Errado 2 (PE2), the 30MW solar thermal power station using its proprietary solar field technology, has been completed and is in operation since August 2012. PE2's solar boiler includes a mirror surface of 302,000m2 making it the world's largest operational solar thermal power station based on linear Fresnel collector technology.

2012,Himin solar supplied one 60 tons solar water heating system for North Korea Grand Emperor Hotel. This project proposal introduced the brief of project, local climate situation and environment , design parameters and equipment selection etc. And also gave detailed system design principal and specialist. This project set up the design consideration for promoting solar water heating project for all over the world. It has the very big meaning to strengthen the international cooperation.

In 2009, himin solar energy for Vietnamese cashew drying plant, provide daily water supply 4 tons of solar hot water system, the project covers an area of 194.4 square meters, heating for the factory to provide about seventy percent of the calories.

In October 2011, himin solar energy in Sweden, a swimming pool for the water park, provide daily water supply 40 tons of hot water system, this system covers an area of 815.9 square meters, the maximum output power of 313 kw, can save 355 kilowatts of electricity every year.

In October 2013, himin solar energy to provide hot water for a hospital in Malaysia, the project has a total area of 432 square meters, the water heater net covers an area of 186.6 square meters, the maximum output power of 164.3 Kw.

In August 2014, Himin exported 1025 sets of solar water heater for the commercial hot water project in Zimbabwe. The photo showed the loading of the solar water heaters.

Himin Solar Co.,Ltd supplied solar water heating project for Olympic shooting range, this project had absorber area 290.5M2, and adopted the mode of the forced circulation plus auxiliary electric heating, with daily water supply 20 tons, realized water supply for 24 hours, guaranteed the application of Olympic stadium for Olympic Games.

Himin Solar Co.,Ltd supplied a solar hot water project in Costa Rica. This project used pump circulation, equipped with auxiliary electrical booster. Daily water supply is 20 tons, which ensures hot water in 24 hours.

In July 2013, Himin Solar built the 200 kw solar PV power station for the First Chemical in Japan. The plant went on grid successfully in the end of 2013.

The project was built in year 2010, with total heat collecting area 2471.96 square meters. The system operates in an indirect way and with pressure. The heat transfer medium is glycol solution. It provides 6.15 million kcal heat each day in winter. For room heating, the indoor temperature can reach up to 22-26℃. It saves 7956Kwh electricity every day, equal to saving 900 tons of standard coal, reducing 2385 tons of CO2, 7.65 tons of SO2, and 6.66 tons of nitric oxide emission, and reducing 3.32 tons of dust discharge, 260 tons of furnace clinker each year.